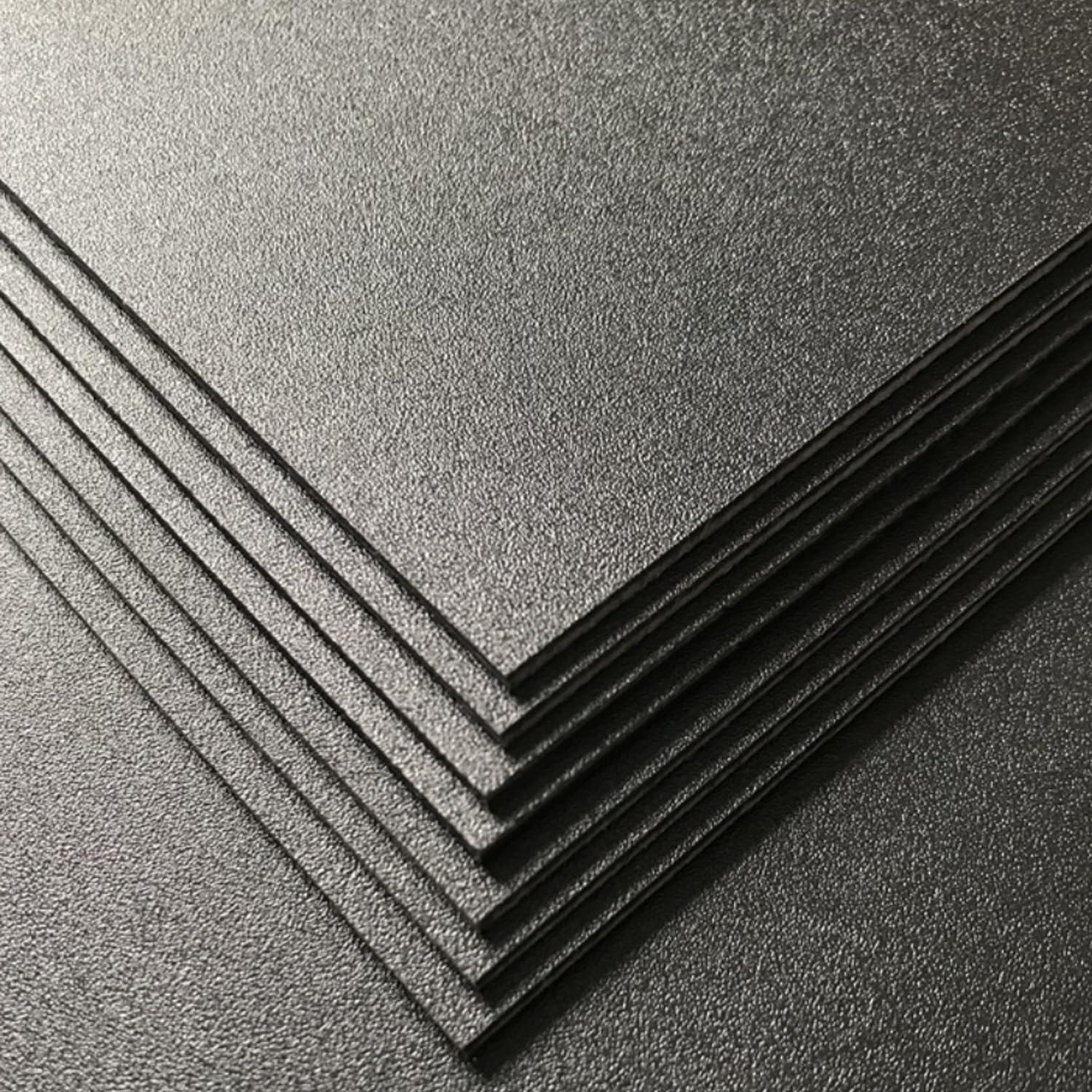

Introduction to ABS Plastic Sheet

A chieved with ABS plastic sheets, SM coextruded technology, an ideal thermoplastic material that's a reliable durable and smooth finish. An engineered plastic material, it offers excellent balance of strength, chemical resistance, and affordability. ABS sheets are in high demand in automotive and construction as well as the advertising and furniture manufacturing industries because of their light weight, strength, weatherability, flame retardance and formability. They are cuttable, thermoformable, drillable and printable – for the best industrial & decorative applications. With advanced manufacturing needs for both aesthetic and functional applications, ABS plastic sheets have become one of the most popular materials used in business today.

Important Characteristics of the ABS Sheets

One of the more important benefits of the ABS plastic sheets is its great toughness. They are resistant to breakage under pressure and keep constant dimensions even when subjected to high heat. Theres a natural gloss on the surface which makes them easy to paint, laminate or simply print on digitally 3d Wpc Wall Panel Price also offer high electrical insulation and moisture resistance, making it a good material for electronic housings and interior paneling. They provide superior machinability among the thermoplastics, and have a lower processing cost. These are some qualities that making companies looking for a reliable ABS Sheet Manufacturer look for continuity on material, uniform thickness and custom finish from their well-networked suppliers.

Industrial Applications Across Multiple Sectors

The flexibility of ABS plastic sheets is what makes them so very popular in industrial use. In automotive, they are molded into dashboards, trims and protective panels. In the construction industry, ABS is used as partition boards, interior decorative boards, thermoformed sheets (including acid etched and other processed glass or mirror). They are also very widely used in signage, branded houseware equipment, machines, furnitures, displays, retail fixtures & settings etc where the high strength-to-weight ratio makes them an excellent choice for many different applications. ABS is also used in various container type applications such as the corridor (380) and bulkhead liners of aircarft. Its properties get it made into maracas. Notably, buyers comparing decorative materials typically compare ABS with wall solutions as they do their research on 3d Wpc Wall Panel Price, both are selected for their hard-wearing and design friendly characteristics in today's interiors.

Increased Demand in the Indian Plastic Industry

Growth of the infrastructure in India’s manufacturing industry and consumer goods consumption have contributed a great deal to increasing usage of ABS plastic sheets. Today, a lot of Plastic Sheet Manufacturers In India are using state-of-the-art extrusion technology to ensure that sizes and quality are the same each and every time. With localization, the cremation equipment dependency on imports has decreased leading to faster supply chain and competition led pricing. Indian ABS sheets are in demand all over world, because they meet international quality standards and suit to flexible manufacture. With the industry needs for strong material that even is versatile and affordable, abs sheets are a growing market in the plastic letdowns industry of Bangladesh.

Customization, Finishes, and Fabrication Benefits

The design of ABS plastic is almost custom, leaving no doubt for assumed industrial applications. They can be manufactured in many colours and thicknesses (from 1 card to 7 cards), with numerous textures (including no texture) both for the front and back of the card, gloss emulsion finishes or matte finish. They can readily be cut, bent or vacuum-formed to create intricate shapes without beating their structural integrity. They are compatible with adhesives and mechanical fasteners for installation flexibility. UV-stabilized and fire-retardant grades are also manufactured for specific applications. These profile features provide specifiers and designers with the ability to select ABS Sheet Manufacturer as a structural element while serving as a decorative surface, which can add visual personality to any product or environment.

Sustainable and cost-effective in the industrial production of today

In this ecologically-sensitive industrial climate, ABS plastic sheets have an edge since they are recyclable and there is minimal waste during the fabrication process. This has resulted in extended service life and thus longer periods between replacements, which helps to lower lifecycle costs. ABS sheets are easier to clean than wood or metal and can be wiped down with a sponge. Their carrying about are further facilitated given that they are light in weight reducing transportation costs and work during erection. For those companies looking for a cost-effective but consistent material, ABS is one of the best options in terms of sustainability and performance. This cost-effectiveness is just one reason that industries throughout the world are increasingly turning to engineered plastics for structural and aesthetics applications.

Market Competition and Supplier Selection

Choosing the best vendor is an excellent way to get high-quality ABS plastic sheets. Buyer pays attention to manufacturing ability, quality management and control system certificate, available customizations, past export sales history. Reliable vendors maintain the quality of raw material used and follow industry standards that allow them to carry stringent inspections at every phase of production. Notable among the established vendors, we have Singhal Industries Private Limited with its extensive products and industrial distribution. Collaborating with experienced manufacturers can help business stay consistent in products, reduce the risk for material failures, and ensure projects are completed on time - especially those which require heavy building or industrial construction applications.

No matter the reason, ABS sheets are still a smart decision Conclusion

ABS plastic sheets still the most popular architectural plastic sheet material with an average low cost thermoplastic combination of good strength and impact resistance With a wide array of customization options, these panels are ideal for both residential and commercial applications, from the most traditional to the cutting-edge India’s rise as a production hub has made high-quality sheets more affordable and accessible to businesses Whether they are used for car parts, interior design signage and more, Plastic Sheet Manufacturers In India continue to be a versatile option balanced between aesthetics durability and affordability that will remain an integral part of future manufacturing evolutions

Frequently Asked Questions (FAQs)

Is it easy to form ABS sheets by thermoforming?

ABS Sheets have very good thermoforming properties Firms like Singhal Industries Private Limited manufacture sheets suitable for bending, moulding and forming into various industrial fabrication and custom product applications.

Are ABS plastic sheets recyclable?

Absolutely, ABS sheets are 100% recyclable and it can be reprocessed into new plastic products. Ethical manufacturers such as Singhal Industries Private Limited encourage sustainable manufacturing and use of materials to aid eco-friendly industrial production.

Which ABS sheet thickness is best?

The weight assumes that it is at the required felling thickness for load bearing and stiffness, and structural use. Vendors are guiding the buyers how to choose sheet thickness for construction, fabrication and decoration purpose such as Singhal Industries Private Limited.

What Are Some of the Most Common ABS Plastic Sheet Applications?

ABS Sheets are common in automotive trim, blank plates for vessels & aircrafts, panels & construction boards. a gination boards. c boards. g board signs, machined housings and covers. food industry i.e chopping board/ packing.

Who is the largest supplier of ABS Plastic Sheet?

There are many companies who supply this but reputed Indian manufacturers such as Singhal Industries Private Limited known for producing consistent quality, great production capacity with closed loop processing to avoid reprocess of ABS Extrusion sheet, good distribution network and customer service available in the world.