Semiconductor Clean Room Instruments Market Expands: Precision & Contamination Control Drive Industry Growth

Market Estimation & Definition

Semiconductor clean room instruments are specialized tools and equipment used to maintain ultra-clean environments required for semiconductor fabrication. These instruments include air filtration systems, particle counters, wafer handling systems, laminar flow benches, contamination control equipment, and monitoring devices. By controlling dust, airborne particles, and microbial contamination, these instruments ensure high yield, reliability, and precision in semiconductor manufacturing processes.

The global semiconductor clean room instruments market is witnessing robust growth due to the increasing demand for semiconductors in consumer electronics, automotive, industrial automation, telecommunications, and data center applications. With advanced fabrication technologies requiring smaller nodes and tighter tolerances, clean room instrumentation is critical for achieving defect-free production.

Request Free Sample Report:https://www.stellarmr.com/report/req_sample/Semiconductor-Clean-room-Instruments-Market/1995

Market Growth Drivers & Opportunities

1. Rapid Expansion of Semiconductor Manufacturing

The growing demand for memory ICs, logic chips, sensors, and microprocessors drives the need for advanced clean room instruments. Increasing semiconductor production, particularly in Asia-Pacific countries like China, Taiwan, and South Korea, is a major growth driver.

2. Miniaturization & Advanced Node Technologies

As semiconductor nodes shrink to 7nm, 5nm, and below, the risk of contamination increases. Precision instruments for particle monitoring, wafer handling, and contamination control are increasingly necessary to maintain high yield and product quality.

3. Stringent Quality & Reliability Standards

Semiconductor manufacturers operate under strict quality requirements for defect rates, reliability, and process repeatability. Clean room instruments ensure compliance with ISO standards and other industry benchmarks, making them essential in modern fabs.

4. Adoption of Automation & Smart Manufacturing

Automated clean room systems and smart instrumentation reduce human intervention, minimize errors, and optimize monitoring. IoT-enabled instruments provide real-time analytics for contamination control, enhancing operational efficiency.

5. Growth in Emerging Semiconductor Applications

The rise of AI, IoT, 5G, automotive electronics, and electric vehicles increases production of specialized chips and MEMS devices, expanding the demand for high-precision clean room instruments.

What Lies Ahead: Emerging Trends Shaping the Future

-

IoT-Enabled Clean Room Monitoring

Instruments equipped with sensors, cloud integration, and predictive analytics enable proactive contamination management and process optimization. -

Energy-Efficient & Sustainable Equipment

Manufacturers are increasingly adopting low-power, energy-efficient clean room instruments and systems to reduce operational costs and environmental impact. -

Advanced Particle Detection & Air Filtration

Next-generation particle counters, air shower systems, and filtration technologies improve contamination control for ultra-high precision semiconductor fabrication. -

Integration with Automation & Robotics

Robotic wafer handling and automated inspection systems enhance productivity while maintaining stringent cleanliness standards. -

Global Expansion & Regional Manufacturing Hubs

Growth in semiconductor fabrication facilities in Asia-Pacific, North America, and Europe drives demand for clean room instruments tailored to regional requirements and standards.

Segmentation Analysis

By Instrument Type

-

Particle Counters & Monitoring Systems

-

Air Filtration Systems (HEPA/ULPA Filters)

-

Laminar Flow Benches & Workstations

-

Wafer Handling & Transport Systems

-

Contamination Control Equipment (Gowning, Air Showers)

-

Metrology & Inspection Instruments

By Application

-

Semiconductor Fabrication

-

MEMS & Microelectronics Manufacturing

-

LED & Optoelectronics

-

Photovoltaics & Solar Cell Production

By End User

-

Semiconductor Manufacturers

-

Research & Development Laboratories

-

Contract Manufacturing Organizations (CMOs)

By Region

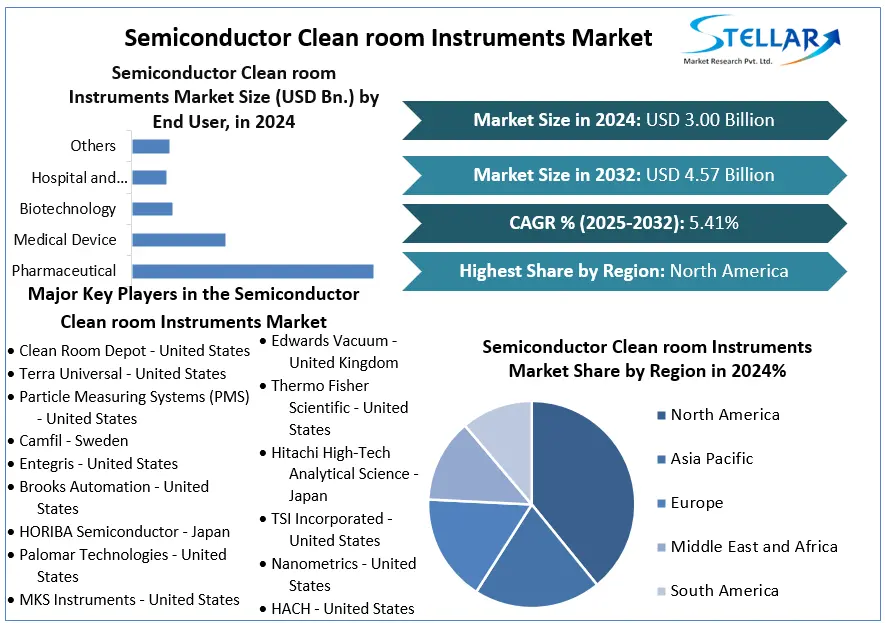

North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa. Asia-Pacific dominates the market due to high semiconductor manufacturing activity, while North America leads in R&D adoption and high-precision instruments.

Country-Level Analysis: USA & Germany

United States

The U.S. semiconductor industry drives high demand for advanced clean room instruments. Leading chip manufacturers and fab operators invest heavily in precision instruments, automation, and smart monitoring to maintain high yields and product reliability. Research-intensive fabs and technology centers also stimulate demand for innovative contamination control solutions.

Germany

Germany’s semiconductor and industrial electronics sector emphasizes precision manufacturing, quality control, and R&D innovation. Demand for clean room instruments is driven by automotive electronics, industrial automation, and MEMS device production. German fabs increasingly adopt energy-efficient, IoT-enabled, and automated clean room instrumentation.

Competitive Landscape & Supplier Dynamics

The semiconductor clean room instruments market is competitive, featuring established global players and specialized regional manufacturers. Key factors influencing market competitiveness include:

-

Accuracy and sensitivity of contamination monitoring instruments

-

Automation and integration capabilities

-

Energy efficiency and sustainability

-

Compliance with international standards and certifications

-

Customization for specific semiconductor manufacturing needs

Companies that provide innovative, reliable, and technologically advanced instruments while supporting process automation are poised to capture significant market share. Partnerships with semiconductor fabs and research institutions also strengthen market positioning.

Press-Release Conclusion

The Semiconductor Clean Room Instruments Market is set for strong growth as semiconductor fabrication continues to advance in complexity, scale, and precision. Demand is driven by miniaturization, quality standards, automation, and the rise of applications such as AI, IoT, and electric vehicles.

For manufacturers of clean room instruments, the market offers opportunities to innovate, integrate smart technologies, and expand into emerging semiconductor hubs. As global semiconductor production grows, advanced clean room instrumentation will remain indispensable for ensuring defect-free manufacturing, operational efficiency, and compliance with industry standards worldwide.

About us

Phase 3,Navale IT Zone, S.No. 51/2A/2,

Office No. 202, 2nd floor,

Near, Navale Brg,Narhe,

Pune, Maharashtra 411041

sales@stellarmr.com